Laser marking and engraving

ES LASER

For your laser marking and engraving applications, our specialists have developed the ES LASER.

Its industrial design, high quality and performance give you the perfect solution for marking metals and plastics. With this laser, you get efficient, precise and fast laser marking. The ES LASER can be used on an almost unlimited number of materials!

Many industrial companies trust us and use this laser for traceability (laser marking that lasts over time without damaging the product), laser marking of logos, laser applications for self-lighting, laser serialisation, etc.

ES LASER, a specialist in high-tech industrial lasers, also integrates robotics, vision and rotary tables into your projects.

ES LASER offers a range of lasers and laser stations for all types of applications including laser marking.

Your project requires special features, entrust your project to our experienced team, dedicated to the design and manufacture of special laser machines.

Applications

- Engraving

- Marking

- Decoration

- Texturing

- Selective removal

Materials

- Metals

- Plastics

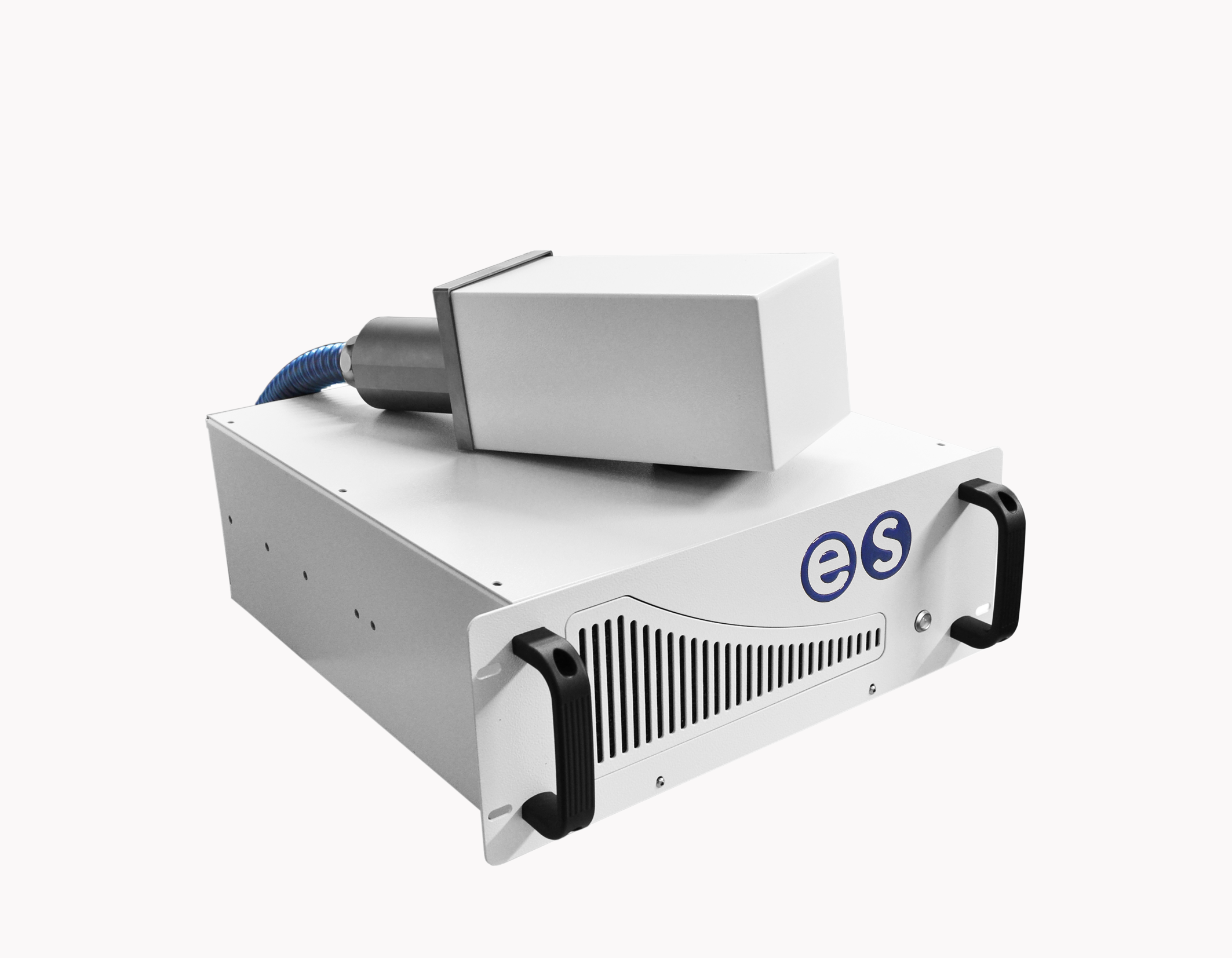

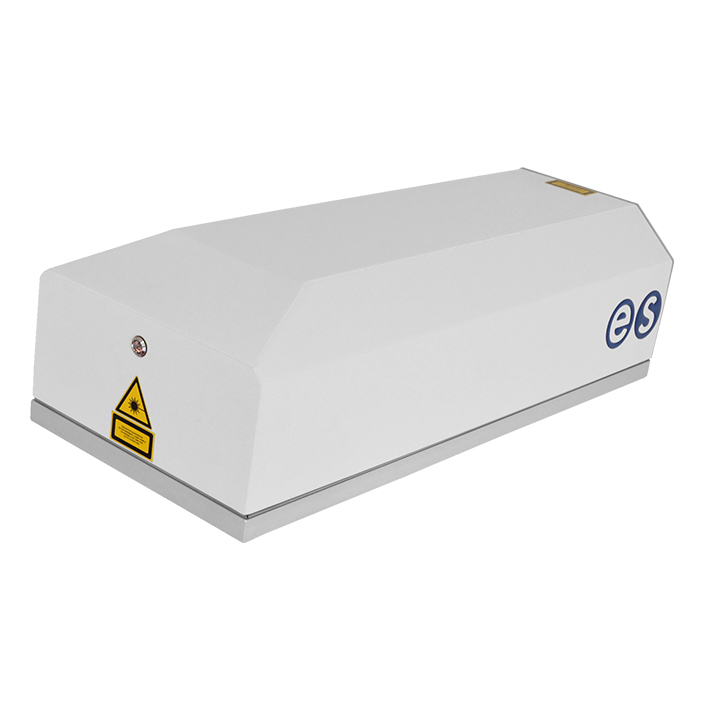

Compact and robust

The technologies used in the design of the ES LASER allow us to offer lasers of small dimensions and therefore easily integrated into production lines. In addition, the ES LASER can also be simply placed on a table for custom work. The galvanometric head can be integrated vertically or horizontally. The control module is also compact and can therefore be easily integrated into a production machine.

Competitive prices

The work of our Development Team has led to the implementation of innovative and effective technical solutions.

These allow us to offer you very competitive prices, without neglecting the quality of the product.

Industrial design

As with all systems designed and manufactured by our engineers, the ES LASER range has a high-tech industrial design. These lasers are therefore perfectly suited to the requirements of integration on the production site and can also be used as stand-alone stations.

Specifications

- Compliance with European Laser and Machine Safety Standards

- Fast and high definition marking, consistent quality

- Industrial design, specially designed for easy integration

- Easy to maintain

- MTBF > 100,000 operating hours

- User-friendly and intuitive marking software

Industrial laser ES LASER

| Central wavelength | 1 064 or 1 070 (CW) | nm |

| Laser power (max.) | 20 / 30 / 50 / 100 | W |

| Working area (max.) | 300 x 300 | mm |

| Cooling system | air |